TCL highlights smart display panel manufacturing capability

The fully automated system reduces the manufacturing cycle, enhances production efficiency, and lowers defect rates.

The Asian manufacturing industry is on the cusp of a significant growth phase, driven by the rapid development of smart manufacturing capabilities and the expanding manufacturing bases in the region. Whilst companies in this sector face various challenges in implementing these advanced technologies, they also encounter numerous opportunities for growth in the midst of the ongoing digital transformation sweeping through the industry.

One company at the forefront of this transformation is TCL, a global intelligent technology company with a rich history dating back to its founding in 1981. TCL's core mission revolves around empowering people to solve their problems through innovative technologies. Positioned strategically across three core industries, TCL has played a pivotal role in advancing globalisation through its extensive network of 48 research and development centres and 32 manufacturing bases worldwide. Its products and services now reach customers in over 160 countries, solidifying its status as a prominent player in the global market.

One of TCL's standout subsidiaries, TCL CSOT (TCL China Star Optoelectronics Technology), has embarked on a transformative journey characterised by the introduction of cutting-edge smart technologies designed to revolutionise the operations of its display manufacturing facilities. This strategic move has propelled the company into a new era defined by enhanced efficiency and unwavering commitment to sustainability.

Established in 2009, TCL CSOT has swiftly risen to prominence in the display industry, offering a diverse array of panels spanning from large-size displays to smaller screens. These versatile panels find applications across a wide range of sectors, including television, commercial displays, information technology, medical devices, vehicle-mounted displays, augmented and virtual reality, and professional displays. Presently, TCL CSOT operates an extensive network of nine state-of-the-art panel production lines and five cutting-edge module bases strategically located in key Chinese cities such as Shenzhen, Wuhan, Huizhou, Suzhou, and Guangzhou, as well as in Tirupati in India. This commitment to infrastructure expansion underscores TCL CSOT's impressive total investment, which surpasses an approximate figure of CNY 260 billion (approximately US$36.5b).

The integration of smart technologies into TCL CSOT's manufacturing processes marks a significant milestone, reflecting the company's unwavering dedication to optimising every facet of its operations. The overarching blueprint encompasses several pivotal objectives, including the enhancement of human efficiency, the elevation of yield rates, the optimisation of operational and resource efficiency, and the reduction of energy consumption. These concerted efforts culminated in TCL CSOT's achievement of Level 4 certification in national intelligent manufacturing capability maturity in 2022, a testament to its relentless pursuit of intelligent manufacturing excellence.

A standout feature of TCL CSOT's commitment to technological advancement is its pioneering application of 5G+AR remote collaborative guidance within its manufacturing facilities. By harnessing the transformative potential of 5G connectivity and augmented reality (AR), the company has established seamless communication channels and remote guidance capabilities, thus streamlining processes and ensuring the highest levels of precision in its operations. Additionally, the utilisation of 5G+IoT for data collection and the deployment of 5G+ automated inspection robots in specialised areas have resulted in substantial improvements in data accuracy and process efficiency.

Environmental sustainability stands as another top priority for TCL CSOT, exemplifying its commitment to responsible manufacturing. The company has embarked on comprehensive initiatives aimed at eliminating hazardous substances from its supply chain. In 2022, TCL CSOT has undertaken 657 energy-saving measures. These initiatives encompass diverse areas, including air pollution control, noise pollution control, solid waste management, and the optimisation of energy resource consumption. For instance, the Suzhou CSOT factory has initiated 50 energy-saving technical improvement projects, yielding significant reductions in electricity consumption and carbon emissions. Similarly, the Shenzhen CSOT factory has executed 249 energy-saving projects across various units, with a sharp focus on process energy conservation, management energy efficiency, and parameter optimisation. These collective efforts have resulted in substantial energy savings. TCL CSOT achieved electricity savings of 96.82 million kWh and reduced carbon dioxide emissions by about 87,000 tons in 2022 alone, accompanied by significant water conservation facilitated by innovative and advanced water recycling systems in module bases.

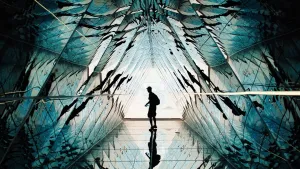

In the highly specialised realm of LCD panel production, TCL CSOT maintains stringent environmental standards to ensure product quality and safety. A particular emphasis is placed on protecting against harmful blue light waves and impurities during the production process. This necessitates the use of yellow light to filter out these elements effectively. Furthermore, TCL CSOT enforces strict cleanliness protocols, with all personnel required to wear antistatic cleanroom suits. The factory floor itself boasts a state-of-the-art honeycomb-like pattern of small holes and utilises CSOT's proprietary barrel filtration system. Air is meticulously circulated through a six-metre-deep CSOT barrel for cyclic filtration, ensuring the highest standards of cleanliness and quality.

Thin glass sheets, a critical component of the manufacturing process, undergo rigorous cleaning through a UV disinfection machine and water free of conductive ions. This meticulous cleaning process is indispensable, as various colour films are continuously applied to the glass during the production of liquid crystals. To optimise space utilisation and enhance production efficiency, the factory layout strategically positions the colour film zone, array zone, and box-in zone on the same floor. This innovative approach creates a high-density arrangement of machines that positions TCL CSOT as a global leader in production capacity per unit area.

Automation plays a pivotal role in handling the delicate glass substrates, measuring a mere 0.5mm in thickness. An entire section of the facility is dedicated to glass handling, where automated machines equipped with vacuum suction cups efficiently transport the glass. These machines ensure precision, rapid speed, excellent dynamic response, and minimal space requirements, contributing to the company's overall efficiency and productivity.

The innovative manufacturing processes implemented by TCL CSOT have yielded an impressive range of products, each showcasing the company's commitment to technological excellence. Examples include the 85” 8K 120Hz Mini LED OD0 TV, which exemplifies practical applications of Mini LED BLU technology, and the TCL 115” X11G Max TV, boasting world-leading low reflection and soft light screen technology. The latter features a specialized surface treatment that achieves remarkably low reflectance. Additionally, the 49” DQHD 120Hz R1800 Ultra-Wide Curved Gaming Screen stands out with its R1800 curvature, a 32:9 screen ratio, high resolution of 5120x1440, and a rapid 120Hz refresh rate.

Throughout its remarkable journey, TCL CSOT has fostered strong and enduring relationships with over 3,000 suppliers and customers. This extensive network positions the company as a trusted supplier to numerous mainstream consumer electronic brands, solidifying its role as a key player in the global market. Furthermore, TCL CSOT actively collaborates with a wide range of upstream and downstream partners, including laboratories and universities, to explore cutting-edge technologies. This collaborative approach has yielded an impressive portfolio of intellectual property, with TCL CSOT amassing a staggering total of 60,880 global patent applications and securing 24,211 global licenses to date.

TCL CSOT's unwavering commitment to innovation and its agility in adapting to the ever-changing needs of consumers are central to its continued success. By continually integrating smart manufacturing capabilities throughout its industry chain, the company is well-positioned to enhance its overall competitiveness and operational efficiency further. This unyielding dedication to technological advancement and sustainability firmly establishes TCL CSOT as a global leader in the display industry, poised for continued growth and innovation in the years to come.